In the bustling world of manufacturing, efficiency is key. Streamlining processes not only saves time but also enhances productivity and reduces costs. Among the numerous components involved in manufacturing, steel coil handling equipments play a crucial role. Let’s delve into the realm of steel coil handling equipments, exploring their significance, functionalities, and their integration into modern manufacturing processes.

Understanding Steel Coil Handling Equipments:

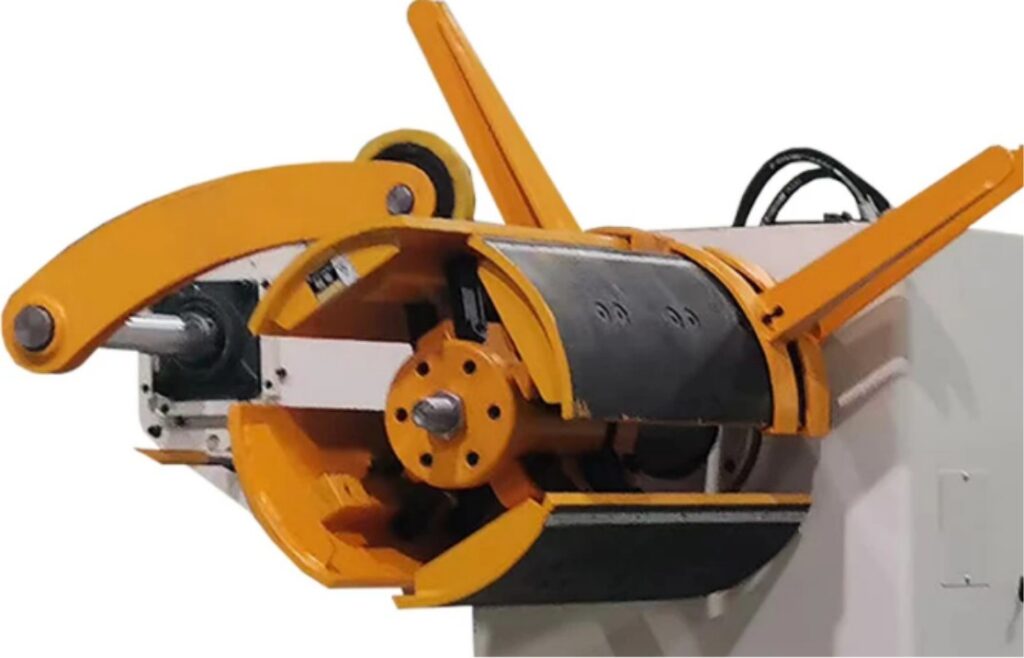

Steel coil handling equipments encompass a wide array of machinery and tools designed specifically for the efficient handling, transportation, and processing of steel coils within manufacturing facilities. From lifting and transporting heavy coils to precise positioning and feeding into processing machinery, these equipments form the backbone of many industrial operations.

Lifting and Transporting Coils:

One of the primary functions of steel coil handling equipments is lifting and transporting coils within the manufacturing facility. This task involves the use of specialized machinery such as coil lifters, cranes, and hoists. These equipments are engineered to safely lift and move heavy coils from one location to another, minimizing the risk of accidents and injuries.

Ensuring Safety and Precision:

Safety is paramount in any manufacturing environment, especially when dealing with heavy materials like steel coils. Steel coil handling equipments are equipped with advanced safety features such as overload protection, anti-sway systems, and remote operation capabilities to ensure the safety of operators and surrounding personnel. Additionally, these equipments are designed for precision handling, allowing for accurate positioning and placement of coils during the manufacturing process.

Integration with Punch Automation Equipment:

Punch automation equipment plays a vital role in various manufacturing processes, particularly in metal fabrication. These equipments are used to punch holes, slots, or other shapes into metal sheets or coils with precision and efficiency. Integration of steel coil handling equipments with punch automation equipment further enhances the overall efficiency of manufacturing operations.

Optimizing Material Flow:

Efficient material flow is essential for maintaining a smooth and uninterrupted manufacturing process. Steel coil handling equipments streamline material flow by seamlessly transferring coils between different stages of production. Whether it’s feeding coils into punch presses or transferring finished products to storage areas, these equipments play a crucial role in optimizing material flow and minimizing downtime.

Enhancing Productivity:

By automating repetitive and labor-intensive tasks, steel coil handling equipments contribute to significant improvements in productivity. Operators can focus on more skilled and value-added activities while the equipments handle the heavy lifting and transportation of coils. This not only speeds up production cycles but also allows for greater output with fewer resources.

Reducing Costs and Waste:

The efficient handling of steel coils not only saves time but also reduces costs associated with labor, maintenance, and material waste. By minimizing errors and maximizing the utilization of materials, steel coil handling equipments help manufacturers operate more cost-effectively. Additionally, the integration of automation technologies further drives down operational costs by optimizing energy usage and reducing downtime.

Meeting Industry Demands:

In today’s competitive manufacturing landscape, companies are constantly under pressure to meet increasing demands for quality, speed, and efficiency. Steel coil handling equipments enable manufacturers to stay ahead of these demands by providing reliable and scalable solutions for handling and processing steel coils. Whether it’s a small-scale operation or a large-scale production facility, these equipments can be tailored to meet specific industry requirements.

Conclusion:

Steel coil handling equipments play a pivotal role in modern manufacturing operations, enabling companies to achieve higher levels of efficiency, productivity, and safety. From lifting and transporting heavy coils to seamlessly integrating with punch automation equipment, these equipments are indispensable assets in the manufacturing industry. As technology continues to advance, the evolution of steel coil handling equipments will undoubtedly pave the way for even greater innovations in manufacturing processes.