The effectiveness of warehouse operations has a major influence on a business’s overall performance in the quickly changing market of today. A warehouse control system plays a crucial role in optimizing these operations by managing the movement and storage of materials within a warehouse. Integrating seamlessly with other technologies, a WCS ensures that everything from order processing to shipping is executed smoothly and efficiently. This system is not just about keeping track of inventory. It is about enhancing the speed, accuracy, and reliability of the entire supply chain.

Let us understand the pivotal attributes of a warehouse control system that can help businesses realize why it is an essential investment.

Real-time data processing

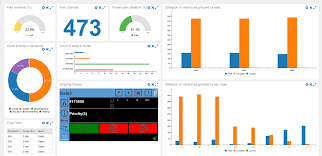

A key trait of a WCS is its ability to process and relay data in real time. This capability ensures that warehouse managers have up-to-the-minute information on inventory levels, order status, and logistical operations. Real-time data processing helps in making prompt decisions that can reduce downtime, optimize inventory turnover, and enhance responsiveness to market demands.

Automation of warehouse tasks

Automation is at the heart of modern WCS. By automating various warehouse tasks such as sorting, storing, retrieving, and packaging, a WCS minimizes manual labor, reduces errors, and increases operational speed. This automation not only boosts productivity but also allows human resources to focus on more complex decision-making and customer service tasks.

Enhanced order accuracy

Order accuracy is vital for maintaining customer satisfaction and loyalty. A Warehouse Control System (WCS) significantly enhances this accuracy by meticulously tracking and managing inventory levels and guiding the picking and packing processes. This precision minimizes errors and reduces the likelihood of returns, ensuring that customers receive the right items swiftly and efficiently, which is crucial for fostering customer trust and repeat business.

Scalability and flexibility

As businesses evolve, so too must their operational strategies to accommodate growth and changing market demands. A robust Warehouse Control System (WCS) proves essential in this regard, offering scalable and flexible solutions that adjust seamlessly to increased order volumes or seasonal fluctuations. This adaptability is crucial for businesses planning to expand or diversify, as it ensures that warehouse operations can scale up efficiently without a drop in performance, supporting a smooth and effective scaling process.

Improved safety and security

Safety and security are enhanced with a WCS due to its ability to monitor warehouse activities continuously and its integration with security systems. Automated systems reduce the need for manual handling of heavy items, lowering the risk of accidents. Furthermore, a WCS can help in enforcing safety protocols and ensuring that only authorized personnel access certain areas or handle specific inventory.

To sum up

A Warehouse Control System is not merely an optional tool but a cornerstone of modern logistics management. Its ability to process data in real time, automate tasks, enhance order accuracy, provide scalability, and improve safety and security makes it an indispensable asset for any business that relies on warehouse operations. Investing in a WCS is investing in the efficiency, safety, and future growth of a company.